In challenging industrial environments, Naishi Insulated Ball Valve plays a critical role in maintaining fluid temperature and operational reliability. Pipelines carrying steam, hot water, or chemical solutions are vulnerable to thermal stress, which can cause equipment fatigue, leaks, or process disruptions. Advanced insulation minimizes heat or cold loss, maintaining stable flow and protecting both pipelines and connected machinery. Properly engineered valves also reduce maintenance needs while enhancing safety for personnel handling critical systems.

Industrial pipelines often traverse long distances, underground or exposed to varying weather conditions. Temperature variations can result in energy inefficiency, condensation, or uneven flow. Insulated designs help preserve consistent thermal conditions, preventing material degradation and equipment malfunction. For large-scale installations, careful attention to mechanical support, thermal expansion, and uniform heat distribution ensures that all parts of the network function efficiently and safely. Industrial plants benefit from reliable performance, minimized downtime, and operational continuity.

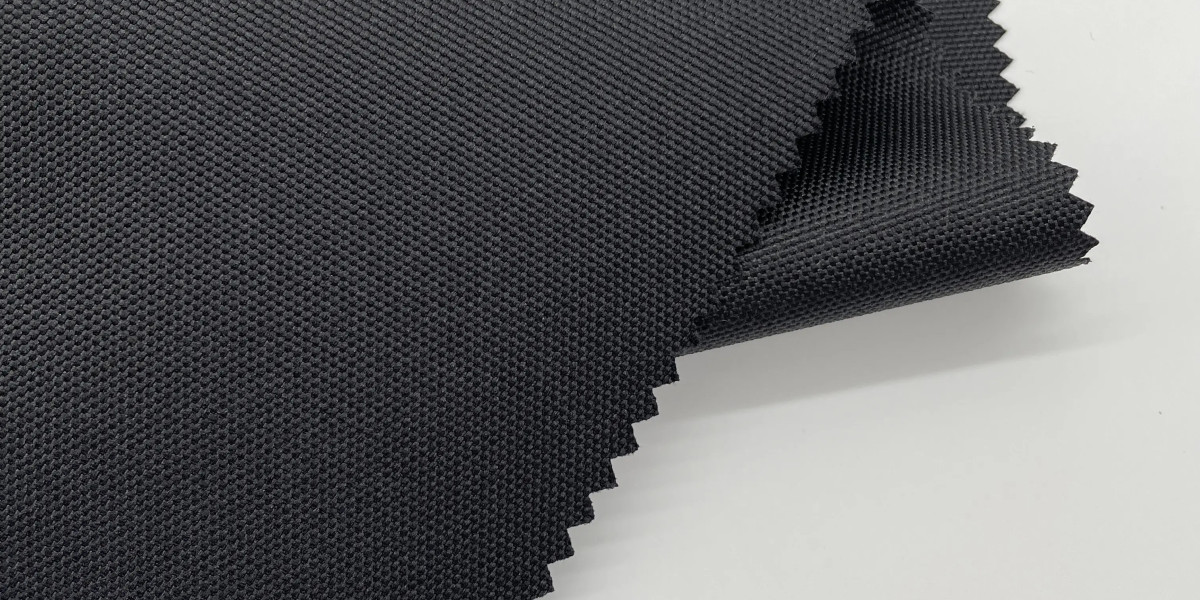

Cold climates and freezing conditions present additional risks, including ice formation, valve blockage, and reduced flow. Proper insulation prevents freezing while maintaining system integrity. Materials are selected for chemical resistance, durability, and long-term thermal performance. Industrial facilities such as HVAC networks, district heating systems, and chemical plants rely on insulated valves to maintain fluid consistency and operational safety. Well-designed systems also reduce hazards for personnel and simplify maintenance procedures.

Energy conservation is another key advantage. Minimizing thermal loss lowers dependence on external heating or cooling, reducing operational costs and environmental impact. Valves constructed with low thermal conductivity materials provide long-lasting protection and reduce thermal stress on pipelines. Inspection and maintenance can be performed without removing insulation, ensuring continuous operation. Properly insulated valves contribute to efficient energy use, equipment longevity, and smooth system performance across diverse applications.

In conclusion, integrating Insulated Ball Valve from Naishi ensures reliable temperature control, protects pipelines against extreme conditions, and enhances operational efficiency across industrial systems. Explore innovative insulated valve solutions and advanced engineering at https://www.ncevalve.com/